I didn't blog about my day the other day, where the MX2 landed sweetly and the landing gear ripped out of the bottom of the plane...

I had flown her for a while, several touch and goes, getting the hang for how she would float into a landing. On my final to stop she landed nicely and after about a foot of roll out the landing gear ripped from the bottom of the plane, taking the entire forward bottom section with it. Post crash inspection I noted that the right wheel hub was broken all the way around. I suspect it failed shortly after this touch down grounding the right landing gear strut and bringing that right side to a sudden and catastrophic halt. This explains why the right wheel pant rolled back into the right wing, and the left wing escaped injury.

In previous repairs the prior owner had heavily built up the bottom, so there were no weak points in the vicinity of the landing gear attachment. The heavy beatings she would take as a gas plane likely weakened the fuse beyond the hard points and after a time she failed. And she failed big. I wasn't sure I could repair it. Given the build up from the previous repair, I was obligated to rebuild her likewise. I think I did a pretty good job, and the weight should be about the same if not lighter (I removed and did not replace a couple of solid wood panels and screws from the original repair).

Ripped clean out.

Cracked the wheel pant that went through the wing. The wheels classically roll back and strike the wing, usually putting holes in both sides. This only caught the right one.

Bottom ripped out. There was a nice pile of debris. If you look closely you can see evidence of the previous repairs.

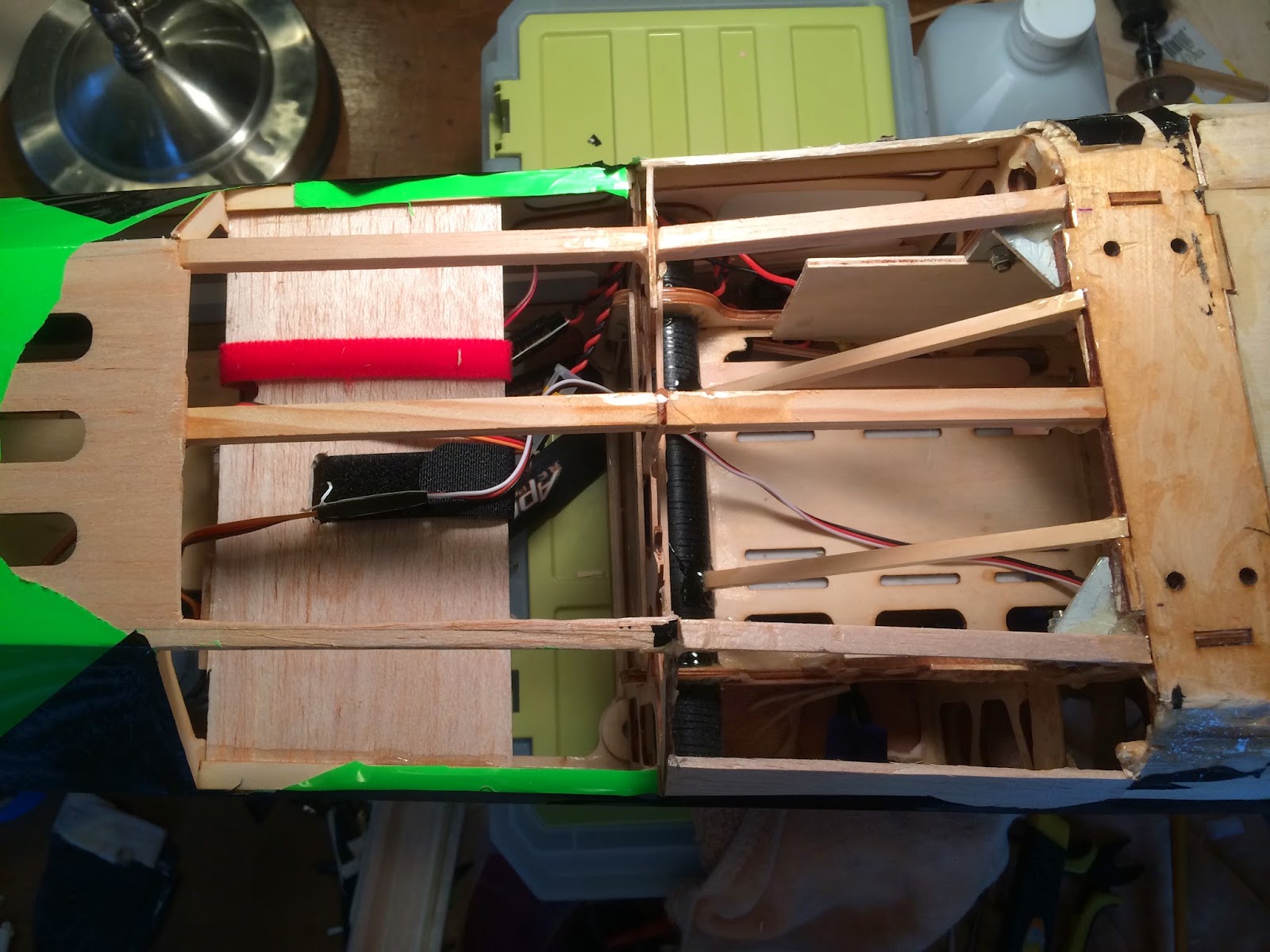

Rebuilding. The right side of the attachment of the gear point to the fuse broke off clean right at the juncture of the metal L bar the previous repairer used, so I had to place it in situ and use epoxy and supporting wood to reattach it.

It ain't pretty, but its strong. You can see how I used wood to make connections and to reattach the hard point to the fuse.

Tongue depressor stringers replacing plywood laser cut frame.

You can see where the laser cut frame wood was torn from the fuse and how I fashioned tongue depressor stringers.

I laid down a hardwood center bar and two hardwood buttresses angled down from the gear hard point connecting it to the wing tube. This directs any aft ward force up and back into the hard support of the fiberglass and carbon fiber wing tube structure. The original repair had a solid sheet of wood between the gear hard point and that first bulkhead aft. I use balsa 4 mm square rod to support the sides along the bottom of the fuse.

You can see the popsicle stick wood I used to reconstruct a bulkhead where the laser cut bulkhead used to be. Some of the bulkhead remained and I used it as foundation.

A better view from fore to aft. In this view I have laid down sheet balsa to smooth out the area in front of the landing gear hard point.

I whittled down that center balsa keel that overlies the hardwood keel, to make it more flat. It looks rounded here as I thought that's what I wanted, but decided to flatten it out some.

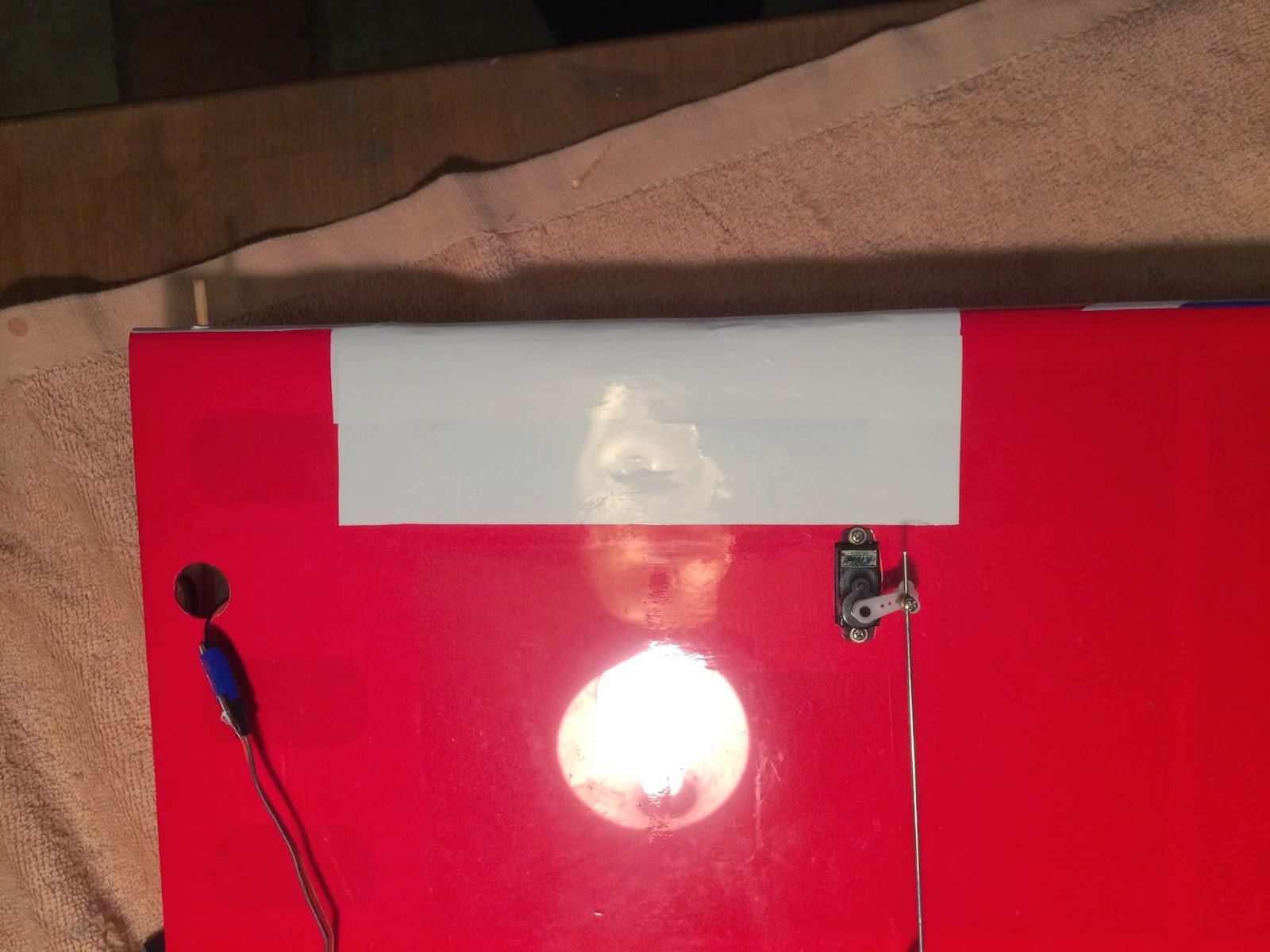

The final cote work. To increase the strength offered by the cote I did it in layers. The front section then the gear hard point and the sides drooping off of it, then one large overlapping strip on each side (they cross in the mid-line at an angle), then a center black strip from the hard point aft bringing it all together. I added the decorative dart as a large white dart, with a smaller white dart on top giving more layer, and then two thinner black stripes dividing the white dart.

I've learned to tack down the edges with the iron and then use a heat gun to shrink it to taut fit. I have to say it came out perfect, with excellent symmetry and clean lines! Some of my best work yet.

I will repair the hole in the right wing today, and have ordered a set of carbon fiber landing gear to replace the aluminum one that I broke by over stressing it trying to straighten it. One friend suggested using heavy duty aluminum, but the CF one came in at half the price, is lighter and stronger, even though it tends to crack rather than bend when severely stressed. I have already repaired the wheel pant with epoxy and CA, and will sand then paint the inner aspect possibly white to contrast with the other side (not sure yet). Once its all done I will post some photos, check her CG and fly her. I hope the repairs don't change her flight characteristics much, she was perfectly balanced.