The wing tube was really just a pair of cardboard guides. All of the wing lift forces were transferred to the fuse only at the two wing mounting lock tabs, secured with one screw on each side used to mount and dismount the wings. Any yaw torque on the wings was transfered to the thin balsa sheeting and stringers, not capable of withstanding that. So when the weeds yawed the wings they tore the sheeting and stringers and the serious damage resulted from a light force applied just wrong. I am replacing them with a carbon fiber tube that traverses the fuse and is firmly secured in all planes. Its not going anywhere.

Ugly patch work. Replanted the formed pieces that had been attached to the cote that laid over it when it was fractured. Lots of epoxy on curved surfaces will be very hard to sand.

As discussed above, the wing mount hardpoint was more firmly attached to the port side, ripping out the entire underside it was attached to. The Starboard side mount popped without taking the fuselage sheeting with it..

I am not entirely confident that the wing mount hardpoints are properly placed and aligned, but that sucker is firmly epoxied now. I would go on to strengthen the surrounding structures for more support.

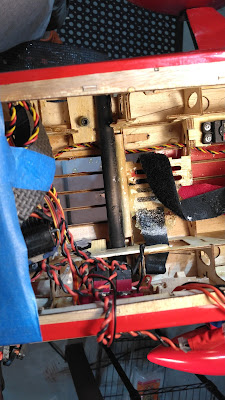

Here you can see the carbon fiber wing spar tube being measured in place. It was nicely perpendicular to the midline. I am sure its aligned properly.

Now installed. You can see the tube is perfectly aligned with the frame. Note that the port (lower) wing hardpoint is against the tube, but the starboard one (top) has a couple of mm of space. I am not confident these are aligned. They are placed where the nearby attached parts made them fit. They may not have been aligned before but worked.

To act as a hardpoint for the wing tube I installed a dowel in front of the wing tube, epoxied in full contact with the wing tube and a frame abutting the bottom tray. The wing tube is going to affect fuel tank fit, but we will deal with that later. This firmly transfers forces to the major fuselage structures rather than just a few stringers and sheeting.

That heavily epoxied ares sanded as best as I could.

Spackled, done for the day to allow all the sparkling a good 24 hr dry before hand sanding smooth.

This repaired area underside was more patch worked than the side was. Thought I had a pic, but alas here it is spackled. After sanding I plan to apply a thinned coat of epoxy, and then will put a Sheet of cote across the stringers there. I am considering laying down a sheet or two of fine fiberglass onto provide a lot of structural strength. I think that may be needless, and add more weight than benefit.

So tomorrow will be telling. I will test fit the wings and see if I will need to come up with a new way to secure them to the fuse if the hard points don't allow an aligned fit. The space difference between the tube, which is true,and the mounting hardpoints suggests this isn't going to go well.

No comments :

Post a Comment