The bag came with two bags inside, nicely done.

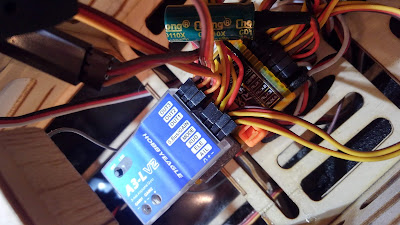

These are the kits parts. The voltage regulator (nice, had never seen one before, put it on my receiver), the gyro, a pair of 3M foam stick pads, and 3 male-to-male short connector wires. There an no intructions, nor any link to a manual.

Google found a v1 manual which more or less is the same. The v1 had 3 gains pots, which I suspect were main, auto-balance and auto-hover. I think v2 pots are main and I have no idea what the second one is.

I mounted it on one end of the 9ch reciever. It's a nice little unit, well constructed, and is programmed with the black button and its LED, which is very easy to operate. VERY easy. Screw it up, factory reset works well, same button. Here's how I know... when I first powered it up one of the connection leads they provided shorted, the magic came out of the wire in a nice little puff. I powered it off and replaced the lead, the brown(black) wire melted its covering off. Restarted it and cranked up the main gain so I could see the surfaces move in response to moving the plane in yaw, pitch and roll. The rudder moved in response to PITCH, and the elevators in response to YAW. WTF? I checked everything and the connections were correct. It was dinnertime so I fired off a quick email to support, knowing I should probably try a hard reset first. After dinner I did just that and the problem was solved. Sent my "never mind" to support. It now works fine. The short must have given it a concussion.

I went into programming and changed it to Mode 2 (On, Off, Auto-balance) since I don't hover, and programmed that to the F-Mode 3 way switch on my DX8 Gen 1. I do wish the order was Off, On, Auto-balance, because if it freaks out and I freak out, I don't want to hunt for the center switch position. I want to shove it to the stop instinctively. I then set the servo frequency to 250hz since I am using digital servos (I figured they should be fine), and they were except the servos screamed, the right wing servo went ape-shit in a noisy jitter then died, I killed the power. So, I am replacing that Tactic TSX47, and since I couldn't confirm the freq, took them back to 50hz, where they work just fine. All the surfaces were oriented fine, no changes. Will need to remeber to turn the gain back down once I get this all set up with the new servo. Didn't want to use the remote gain for now, so left that unplugged; I haven't found the need to dynamically adjust gain, and am worried about having it on a knob that migh turn without me thinking about it.

Why is it so hard to find servo frequency info? A lot of modern devices need that info.

This is a standard gyro setup. Three leads from the reciever to the gyro. All of these systems, (functionally the Alpha6 was one lead each control surface, though it had plugs for each of dual ailerons and elevators, it would not handle them, you still had to use a Y. One of the many issues the device had). One plug for aileron, elevator and rudder. Output is one for each as well, so the ailerons will need to be on a Y-connector. This works for most aircraft.

The Sbach has dual ailerons AND dual elevator servos, which I ran through a transmitter mix when it was set up without the gyro. The right elevator was connected through the ELEV channel, and the left elevator was set through AUX3. The mix was ELEV>AUX3 and they responded to the same control input. Works great, can program the elevators individually through the radio. When you put the elevators on a Y, they move in opposite directions (actually the same direction, but being mirrored it functionally moves opposite). Mechanically the only way to get them to match is to have one connect under the horizontal stab (standard), and the other over. Right now both are the standard under.

So, I have to use a Y-connector. The elevators move in opposite directions.

HOW DO I FIX THIS? How do I make them move in the same direction?

I have that question in to EagleHobby support. I supect the only way is to mechanically over/under the servo control rods, or use a signal inverter, and I am not interested in doing that. To be clear, this is not unique to this gyro, all of these seem to be single channel per axis: pitch, yaw, roll.

I do notice that the ignition light dims with aggressive control inputs. Will need to watch that, may just be a low battery? Nope, 4.1 V per cell. I may need to go to a two battery system if the draw is too high for the voltage. Right now I have a Tech-Aero IBEC on it, but may need to revert to a separate battery and kill switch. I don't think the Tech-Aero IBEC, so, more money for an RCExl Kill Switch...

This is a very nice unit and is now my go to stabilization system. I just may not be able to use it on the Sbach. I'll let you know what I figure out. I may end up forking out for a servo reverser...

UPDATE: Ah, screw it... bought a reverser on a short leash. $12 on Amazon. I like this one because its Turnigy (good quality), I can plug it inline on one servo lead, its very short so no significant resistence added, and not have to have another Y since I already have enough. I had thought that the manual said something about not using them, but I can't find it, so... I'll let you know how it works.

Started as a simple addition for about $35. So far it's cost me $29 for a new servo, $12 for a reverser, $76. And likley a kill. Ouch.

UPDATE 2: Ah, screw it again. Went ahead and bought the RCExl remote Kill Switch too. Last thing I need is a voltage drop on the ignition. There is the capacitor that came with the kit that is on the receiver, I moved it to the gyro and it still flickered a bit. I'll just run two 2S 2300 mAh reveiver packs. What's a little extra weight on a 10cc gasser anyway.... The short was bizarre, still unexplained. The only cause has to be a voltage/amp spike overloaded the wire (it was the lead from the reciver aileron channel to the gyro aileron input, and likely is related to the now dead servo). Is there some amp/voltage draw that is overwhelming the delivery, the capacitor and the capacitors on the IBEC board? That's kinda spooky... I think the best way to handle this is to unload the draws by giving the ignition its own battery pack, so that all the voltage and amps from the reciever pack go to the servos and reciever, and there is no danger of losing the ignition to a spike from servo draw. We'll see.

UPDATE 3 (Final): Nope...

No comments :

Post a Comment