In an odd transmorgrification of the use of gender to describe plugs for the obvious reasons, there is always one hermaphrodite to create confusion for concrete thinkers. That hermaphrodite in our RC world is the "female servo plug".

I bought a boat load of extensions from Hobby King, not knowing why anyone would want a male-male plug, I didn't look closely and while wanting female-male plugs, I bought all male-male plugs. Sending something back to Hobby King is a nuisance, not because they are difficult, you just never quite know whats going on, so I decided to see if there was a simple plug adapter I could buy a bunch of. There is, and there isn't.

To remedy this one has to buy adapter kits and remake the ends. There is no simple plug adapter piece.

When you buy this...

But wanted this... (BTW, I call the upper end the male and the lower end the female, while actually the lower one is more male inside and female on the outside, and technically the wires go INTO the upper one making it also female... hence some confusion. Upper one is male, lower one is female for this discussion, and is the generally accepted nomenclature).

You buy this. These make female ends of male ends. I don't like the Futaba ends because they have that damn edge, but I didn't see JR one's.

Theses are the parts. The original male-male (or female-female, depending on how you look at it) lead, the connector pins on their manufacturing rack (also three I pulled off), and the replacement connector and its sheath.

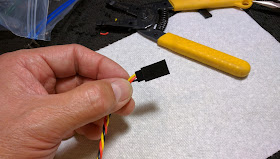

You remove one of the male ends, strip the wires a bit long, and spin them through your fingers to tighten them up.

You slip one of the connectors on. There is a hub the end of the wire goes under, and at the end are two separate sets of squishable grips. Using needle nose pliers carefully crush these down onto the wire to secure it.

They should look like this when you are done.

PAY CLOSE ATTENTION TO THE WIRE ORDER! It must match its opposite end. Close observation will also let one recognize that the pins go in wire side facing up and will softly click, locking into place in the evolving "female" connector.

AGAIN! BE CAREFUL OF THE WIRE ORDER! This should slip in easily, if not, something is not right.

When you are done with the inner plug of the evolving female end, it is decidedly male. If this was all there is and no sheath, this would indeed be correctly identified as the male end, because, well...

But the adapter does get a sheath and it simply snaps on, so it is now the end that gets inserted INTO, so is now the female end. I couldn't tell if it matters which end of the sheath goes on the plug and which remains the accepting opening.

With, you know, pins inside... You can also see, on the lower edge, that Futaba edge blocking the corner.

Thats it. They are a pain to have to do but easily done, and inexpensive. Just please remember that you must get the wire order correct, and that if the pins don't slide in easily, something is wrong.