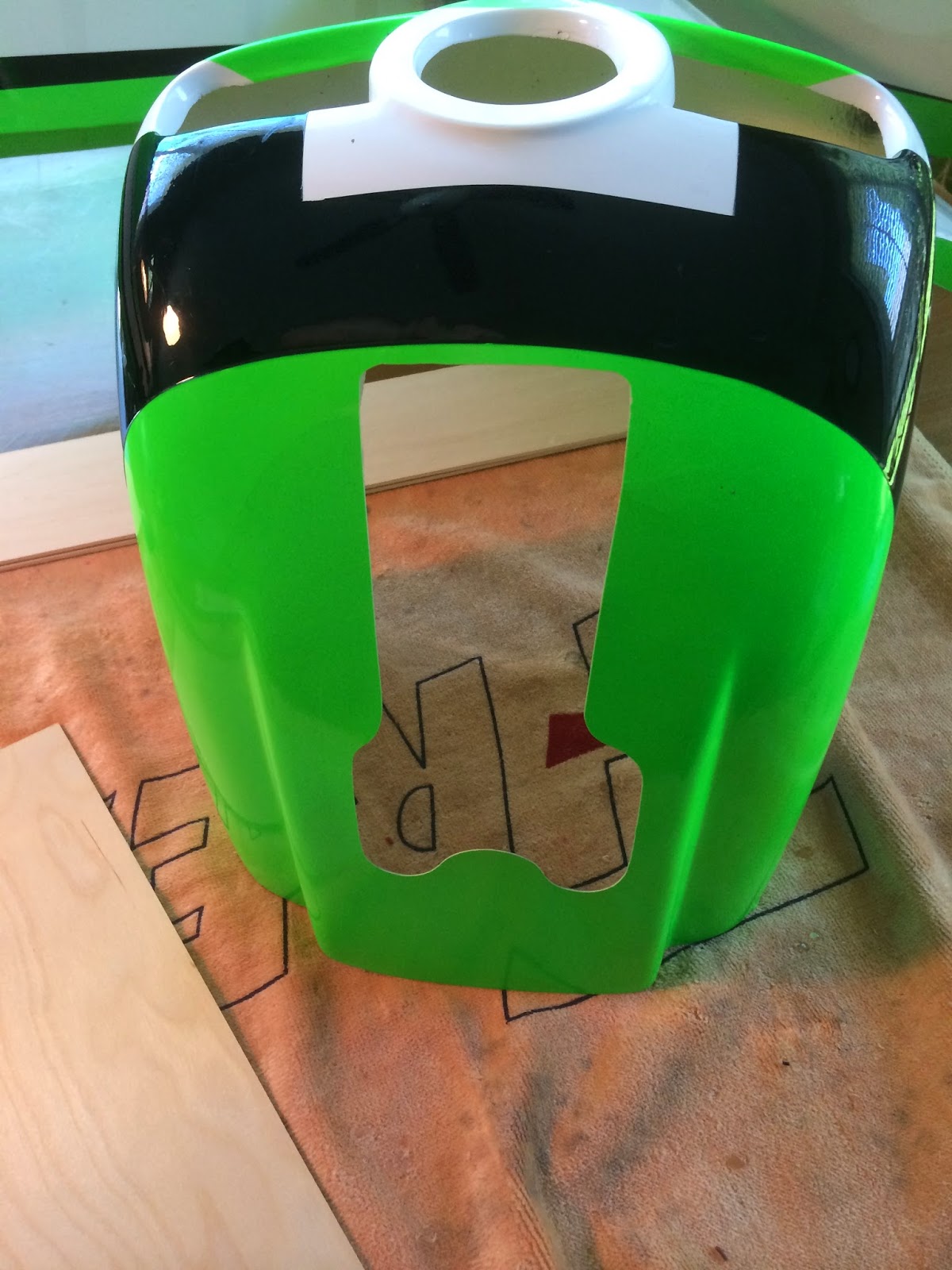

This left the large opening in the bottom of the cowl that used to allow the DLE cylinder head and Pitts muffler exit the airframe. I had an idea to close the opening, with some residual low airflow, but opted instead to set it up with an air dam system to direct high flow air through the airframe. I will have to also make a louver opening aft to allow the high flows to exit. That's for tomorrow.

Yeah... go ahead, say it. That's one Johnson of a hole underneath the cowl.

From the inside.

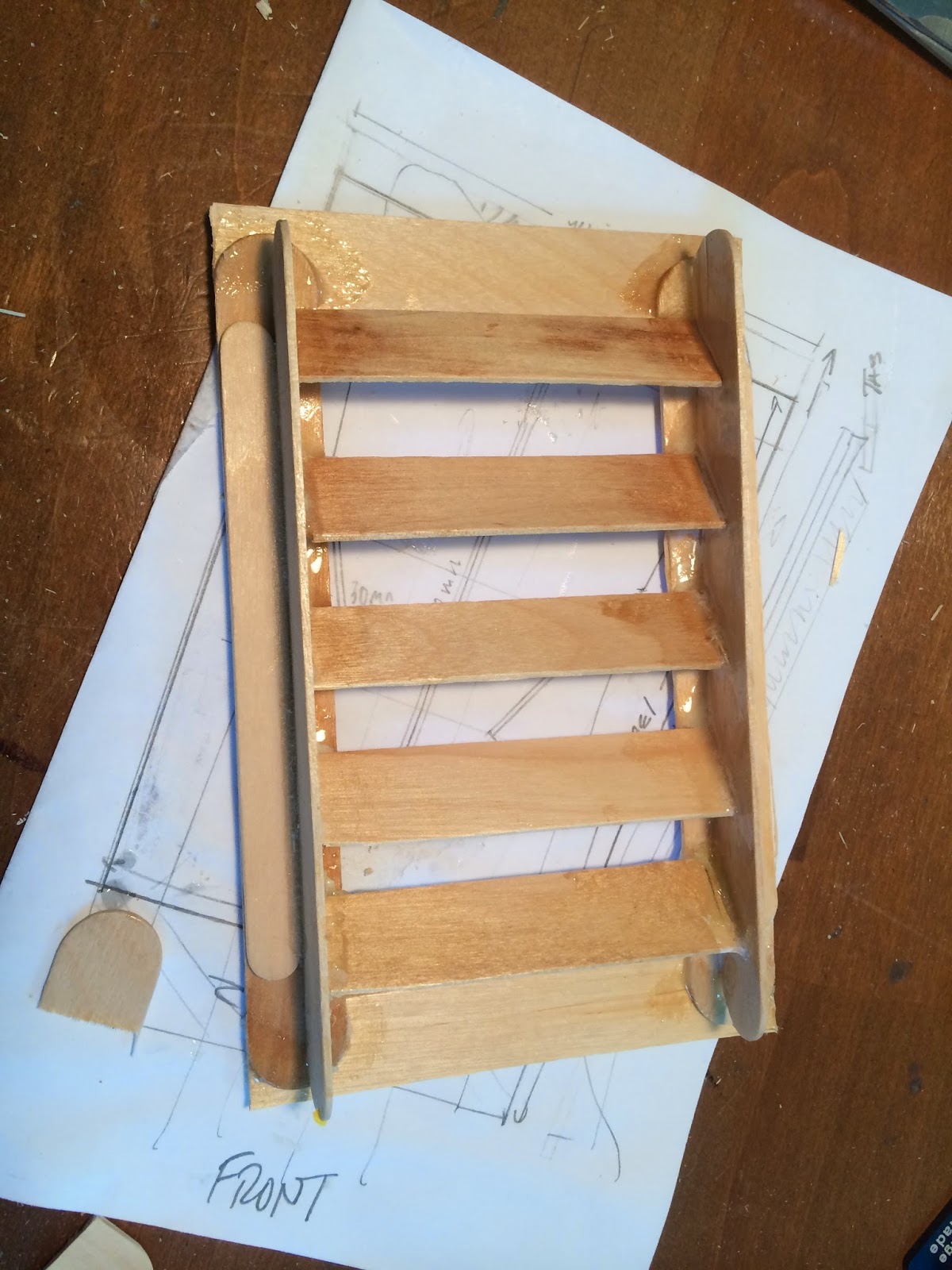

First I mapped out the hole and created a template. The drawing underneath is the first design. These are tongue depressor craft wood.

Allowing CA to dry. Since the wood tends to be acidic, the CA can have a problem drying. Using CA activator can speed the drying. I don't have any, so used some isopropyl alcohol.

I created a jog out of triangle wood. It keeps the angles and spacing consistent.

And does a nice job!

Build finished. Inside...

Outside.

Test fit.

I decided to turn it around. This is after painting.

Finished!

Clean lines. Each louver will create a low pressure behind it drawing air in.

This motor will draw a low of power and create a lot of watts, so this extra airflow will be critical. Tomorrow I will work on the exit louvers. The electronics should be here as the week ends. This plane is really looking great, and is going to fly like a madman; they system should create 2800 watts!

No comments:

Post a Comment